The front cover is made with beech wood, the carcass with plywood.

Motivation

Since a long time I have the dream to build up a tube amplifier for my full range speaker Joe. I found at ebay some Chinese DIY-sets with EL34 for less than 300 US$ which look quite useable. But this kind of amplifiers have only a potentiometer for volume control - but I want at least a remote control. With the time of thinking my requirements were growing:

- four inputs: phone, cd-player, media-player and (perhaps) a DAC

- two volume controlled outputs (perhaps with different gains) for the tube amplifier and for an active box planned in the future

- an output for my headphone

- no switching on/off noise

- a display to show the state of the preamplifier would be nice

- ...

More or less all components could you buy (as diy sets) in China for less money but this are only single objects never thought to work together. Also if you want a small new or a changed software feature - it is not possible because you don't have the source code...

My decision was fallen - I will construct and build up my own preamplifier where all components and the software fit together. With this preamplifier I can drive any tube amplifier very comfortably.

Concept

For a preamplifier you can spend from 50 to a zillion Euros - where you invest and save your money is a very subjective thing. I prefer robust circuits with a long lifetime. One example: electrolytic capacitors influence (or better limit) the lifetime of many electronic devices - here I take only good quality (e.g. ERF, ERY or EKSU series of the German company Frolyt). Normally I don't use very special "audio" parts (e.g. from Mundorf), high quality industrial polypropylene capacitors are good enough for me (e.g. from Wima). As I said: what's important for you can be very individual...

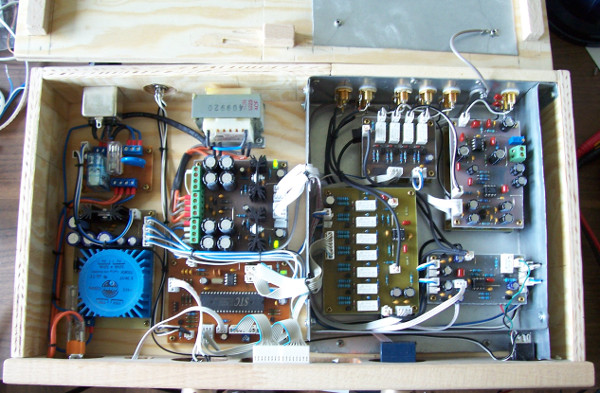

Due to my limited possibilities as amateur in time and tools I split the huge task "preamplifier" into multiple smaller projects: each main function has its own pcb with a maximum board size of 150x100mm. Left and right channel are completely separated.

Components

- Controller board

- RIAA-amplifier for phono

- amplifier for headphone

- input selector

- volume potentiometer

- power supply for the digital part

- power supply for the analogue part

The disadvantage of my modular concept: you spend a lot of time for wiring...

Case / housing

In contrast to the pcb's - I have no plan from the housing... The case was created by guess and by gosh. I have not really the tools to create a (good-looking) metal housing. I found a aluminium housing from a Chinese dealer at ebay for app. 150 Euros. It looks nice but for this price buy other people a complete amplifier. So I decided to make a wood case with a metal shield inside. The metal shield isn't visible so I was able to make with my simple tools (cutting with a pair of snips and bending with a vice).

falk.richter*at*yandex.com

Last update: December 20, 2019