Overview

Joe is a tapered quarter wave tube (TQWT) with the 20cm full range speaker Rockwood / Senon DY-811U. The idea for so a kind of box I found in this Dutch hifi forum. My changes: I arranged the bass tube on the front of the box so that the centre of the chassis is on the same height as my ears on my sofa - 1.05m. I added also a cheap 11mm dome speaker for some super-tweeter experiments but I didn't find any useful cross over dimensioning later. So the tweeter isn't connected and can be left away.

The dimensioning of the box isn't so as in the cookbook. The resonance frequency of the DY-811U is around 95Hz but the length of the tube is calculated for app. 42Hz. I haven't a simulation program for TQWT's but I think this construction doesn't increase the Q-factor of the chassis at its resonance frequency point and harvest a little piece of bass below the resonant frequency. I must say: if the chassis wasn't so cheap I never built up so a kind of box... But it works - there is really a bass fundamental...!

What I don't know: is the effort for a TQWT deserved? Or has a closed housing or a transmission line the similar bass output??? Perhaps you build up an other housing type - please let me know your results.

The name of the box remembers Mr. Joe Cocker. His song "Eye on the prize" from the album "Fire it up" (2012) seems to be written for a full range loudspeaker...

Calculation

This TQWT is calculated like a Voigt pipe. I used the calculation recommendations from the German

Intertechnik forum in its project "Quickly AX-5":

LineLength = 340m/s / (4 * 42Hz) = 2.024m

The damping material reduces the length of the tube by factor 0.9:

LineLength = 2.024m * 0.9 = 1.82m

The diameter of the diaphragm (centre to centre of the surround) is app. 16.5cm, in this way the diaphragm area

is around 213.8 cm². This should be also the start area of the tube. The end area is 2.5 times larger (possible is 2 to 3 times - I used

the golden mean...). The diameter of the bass tube is the half of the diaphragm diameter: 8cm tubes are commercially available.

The length of the bass tube is 1.5 times of its diameter: 1.5 * 8cm = 12cm. I bought a bass tube from Sintron at

Pollin

which has a diameter of 7.8cm and a length of 11.5cm.

Construction

The technical drawing was created with the free and open source program Librecad. Here is the drawing as pdf- and as dxf-project-file. In the bottom of the box is a separate space which contains the cross over network. There is a hole in the ground plate for assembling and service.

I created the housing with a 18mm OSD-chipboard. This material has an interesting surface structure but generates a lot of splinter of wood during the workmanship - be careful. An other material that could be used is a 19mm MDF-chipboard. The one millimeter more material thickness doesn't matter: simple decrease the internal volume. We can be a little bit generous because a TQWT uses a lot of assumptions / rules of thumb and isn't a strong scientific construction (e.g. the end area can be 2...3 times the start area, or: the length of the tube is reduced with factor 0.9 because of the damping material - but there exist a lot of damping materials and all have the same factor???)

I cut all chipboard pieces by myself with my circular hand saw (because I had some OSD-chipboards left) but this is a time consuming work. You have to pay attention to your workpiece and to your reject. Often I forgot to fix the reject and in the moment of cutting through the reject fell down and damaged the workpiece (or my feet :o) )... If you have a good DIY market near at hand - let make the cutting there... Hint: make the front and the rear plates 2mm broader, glue it and remove the additional material with a hand router and mill it flush.

I start the bonding with a side plate and the inner parts which have to be exactly at right angles. In the other case you would get a lot of troubles

when you glue the second side plate (leakproofness):

Next I fixed the cables with hot glue. For this I made a track with the glue, put the cable in and fixed it with additional hot glue. The cable has so

no chance to make any unwanted noise on the side plate. Attention: the glue is really hot and you can easily burn one's fingers...

After this I mixed some filler from wood glue and sawdust and filled the sloping edges:

Damping: I coated all walls with polyester mats (very cheap dust filter for the fume hood, e.g. from TopStar, WundMed or Pollin). Around the chassis and at the ends of the tube I used convoluted foam (sometime used as packing material) but I made no experiments here: I don't know is it needed or would the polyester mates make the same job... After finishing the box and some measurements I put in 100g finely plucked viscose cotton from the tube start up to the full range speaker. This makes the frequency response more linear (in the range 200...500Hz) and is recommended on other TQWT pages too.

Now I made the holes and indentations on the front and rear plates with a hand router and a milling compass (I bought it on ebay from

weyher-holztechnik).

It is important to leave enough material over. The rest I sawn off with a jigsaw. Now I glued both plates on the box body. After drying I removed

the protruding burs with a hand router and made a radius chamfer with the same tool (the paper avoids that sawdust pollutes the damping):

I mounted the soft rubber on the box - it is a little bit easier than on the chassis:

And at the end: now is the time to sand and to paint. I used a transparent varnish for floors and stairs on acrylic-water basis. It drys very fast and doesn't glare.

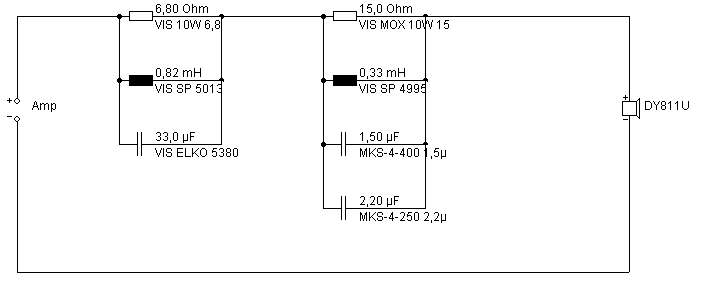

Cross over circuit

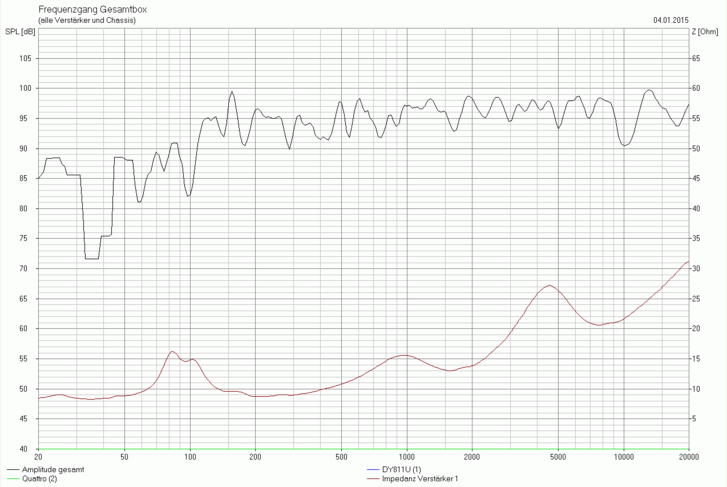

The cross over network was calculated with Boxsim using the real frequency response of the chassis in the housing.

For loudspeaker measurements I'm using Hobbybox 5.1. The best simulation results I got with two trap

circuits and without impedance correction. For the super tweeter I didn't find any good dimensioning so far...

The simulation result (frequency response and impedance characteristic):

I built up the cross over network without a printed circuit board. All parts and cables are fixed with hot glue:

Here is a list with all needed parts.

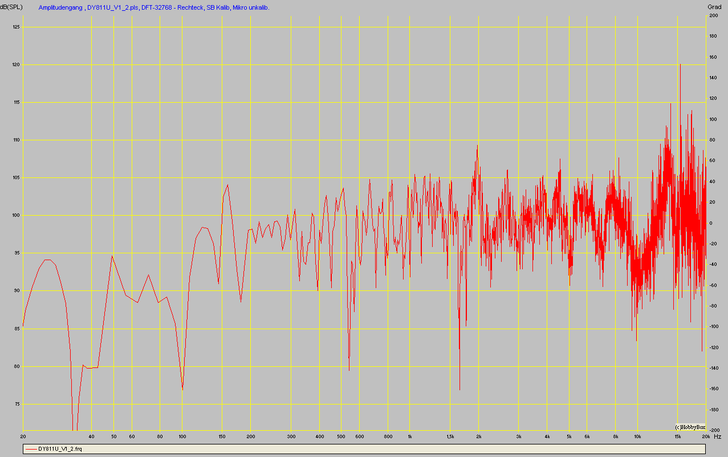

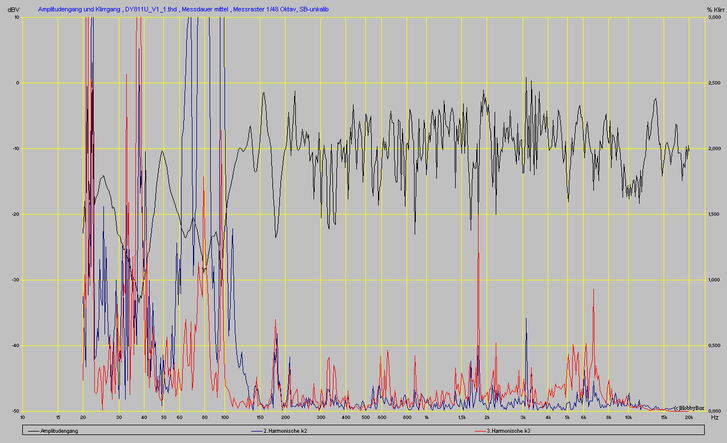

Measurements

The measured frequency response (using the MLS method):

The 2nd and 3rd harmonic distortion and the frequency response using a sinus wave:

Conclusion

After a half year of "hearing" I'm really happy with the construction. I tested it against my "old" two-way box (transmission line with a Visaton WS17E plus Monacor MHD-190 and a flat frequency response): It's clear - a full range speaker is far away from a correct frequency characteristic - but in the direct comparison: the two-way box is nearly a little bit boring...

One disadvantage have all 20cm full range speaker: the angle for the correct reproduction of the high frequencies is very small, you have to sit in the stereo-triangle to enjoy the whole sound spectrum.

I wish you a good time,

Falk

falk.richter*at*yandex.com

Last update: December 20, 2019